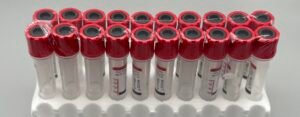

Centrifuge tubes, ie tubular sample containers, can be provided with sealing caps or glands.

According to the volume can be divided into:

Large capacity centrifuge tubes (500mL, 250mL), etc.

Ordinary centrifuge tubes (50mL, 15mL), etc.

Microcentrifuge tubes (2mL, 1.5mL, 0.65mL, 0.2mL), etc.

By material

- Glass centrifuge tubes

Due to the brittle quality of such centrifuge tubes, glass tubes are generally not used in high-speed centrifuges, and the amount of use is not large. - Steel centrifuge tubes

The steel centrifuge tube has high strength, no deformation, heat resistance, freezing resistance and chemical corrosion resistance. - Plastic centrifuge tubes

The advantages of plastic centrifuge tubes are that they are transparent or translucent, have low hardness, can be used to remove gradients by puncture, and are inexpensive. The disadvantage is that it is easy to deform, has poor corrosion resistance to organic solvents, and has a short service life.

According to the shape of the bottom of the tube - Conical centrifuge tubes

Precaution

High-speed refrigerated centrifuge - Those who are not trained and tested cannot use it.

- Select the appropriate rotor and speed, do not use it at the fastest speed.

- Choose a suitable temperature, generally 4°C. Except for organic solvents, it should not be below zero, so as to avoid freezing and damage to the centrifuge tube and rotor.

- Before turning the head, the pipe must be wiped with a hole cleaning rod, and the bottom of the hole must be carefully checked for cracks and white spots. If so, turn around and scrap.

- The volume of solution loaded into the centrifuge tube must be appropriate. Stainless steel tube without cap can only fit 2/3, plastic tube can be loaded on shoulder. The cap must be tightly closed and no leakage is allowed. Empty tubes can be deformed by centrifugation. The use of organic solvents in plastic pipes must comply with regulations.